Rapid prototyping is a vital part of checking a product’s shape, ergonomics and technical function, before investing and going ahead with mass production.

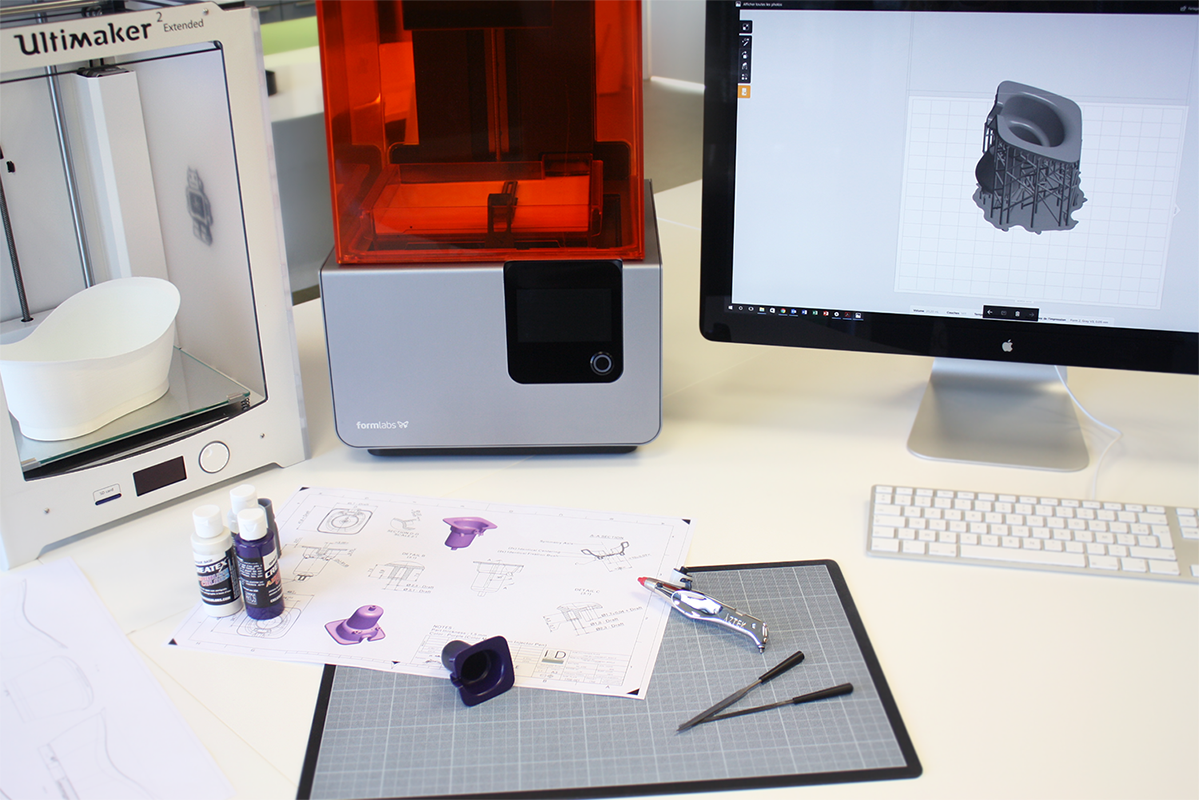

Thanks to our latest generation 3D printers, integrated in our offices, we can, during any stage of your product’s development, quickly print its 3D model. It is an efficient way to make decisions on choices.

i&D uses a fused deposition model 3D printer as well as a stereolithography 3D printer. Our tools print different types of plastic, including flexible and translucent materials. In order to guarantee optimum rendering, which is as close as possible to the final product, we also 3D print wood or stone effects, or apply the coloured paints and finishes of your choice using our airbrushing techniques (shades of RAL and Pantone).

We use two types of 3D printer:

- FDM printer (Fused Deposition Model): Uses a nozzle to deposit filaments of molten plastic, coat by coat

- SLA printer (Stereolithography): Uses a laser to polymerise a photosensitive resin.

FDM printer features:

Print size: up to 230(L) x 225(l) x 305(H) mm

Accuracy: coat thickness, 20 microns (0,02 mm)

Printable materials: PLA, ABS, HIPS, PC, PET, flexible materials, nylon, wood, bronze, stone effects, etc.

SLA printer features

Print size: up to 145(L) x 145(l) x 175(H) mm

Accuracy: coat thickness, 25 microns (0,025 mm)

Printable materials: Classic, flexible, high resistance, castable, dental, etc.

Depending on your requirements, we are also able to sub-contract production of more advanced prototypes to our partners.

We provide support from the production phase right through to the start of manufacture.

With i&D you no longer have to wait for a product prototype. Save time by dealing with a single point of contact.

LASER DIGITALISATION: TAKING A PART TO CREATE A 3D FILE

You have a part but not as a digital file?

3D laser digitalisation enables shapes to be scanned in order to create 3D files. It is useful for reverse engineering tasks and for the design of ergonomic shapes originating from hand made models.

i&D situated in the center of France, between Bordeaux and Lyon, Paris and Marseille has all the advanced tools to meet your demand.

Our design and engineering agency uses a 3D digital scanner.

We analyse 3D digital files and rework them. In this way, i&D is able to take your part and apply modifications, perfect a design, or improve its ergonomics. Once the file has been amended we can carry out rapidly prototype with the help of our 3D printers.

Technical specifications:

Maximum object size: 300 (L) x 300 (l) x 400 (H) mm

Accuracy: 0,2 mm